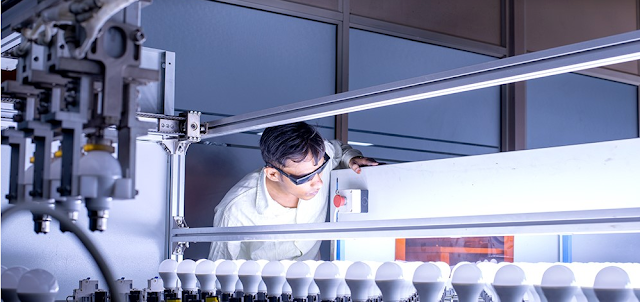

How digitized supply chains can help the manufacturing industry

Data analytics can be used to revolutionize the way companies plan, produce, and deliver goods. Digitized supply chains make use of data from various sources to meet manufacturers' business goals. When a person searches for “How is AI used in the manufacturing industry,” he can learn more about digitization.

Tools available for digitization of supply chains

In digitizing supply chains, various tools and technologies are available to enhance efficiency, visibility, and automation. IoT devices, face recognition, fingerprint authentication, and other digital tools play crucial roles in transforming traditional supply chain operations.

● IoT Devices -- IoT devices such as sensors and RFID tags enable real-time tracking and monitoring of goods throughout the supply chain. These devices collect data on location, temperature, humidity, and other environmental conditions, providing valuable insights for inventory management, logistics optimization, and quality control.

● Face recognition – This technology can be used for identity verification and access control in supply chain facilities such as warehouses and distribution centers. By integrating face recognition systems with security cameras and access control systems, organizations can enhance security measures and prevent unauthorized access to sensitive areas.

● Fingerprint authentication -- Fingerprint authentication offers a secure and convenient method for verifying the identity of employees and authorized personnel. By implementing fingerprint authentication systems for time and attendance tracking, organizations can ensure accurate record-keeping and prevent time theft or unauthorized access to workstations and equipment.

● Digital tools for collaboration -- Collaboration platforms, communication tools, and project management software enable seamless collaboration and communication among supply chain stakeholders, including suppliers, manufacturers, distributors, and customers. These digital tools facilitate real-time information sharing, task assignment, and decision-making, improving coordination and efficiency across the supply chain network.

● Artificial Intelligence and Machine Learning -- AI and machine learning algorithms can analyze large volumes of data to identify patterns, trends, and insights that can optimize supply chain operations. These technologies, which enable predictive analytics for demand forecasting, inventory optimization, and route planning, show how AI is used in the manufacturing industry.

● Robotic Process Automation (RPA) -- RPA software automates repetitive and rule-based tasks in supply chain management, such as order processing, invoicing, and inventory reconciliation. By deploying RPA bots, organizations can streamline workflows, reduce errors, and free up human resources to focus on more strategic tasks that require creativity and problem-solving skills.

Advantages of a digitized supply chain

● Digitization of the supply chain helps manufacturers address the requirements of new customers. A precise forecast of customer demand can be made.

● Planning can be made a continuous process with the help of a digitized supply chain. Manufacturers will be able to react dynamically to changing requirements of constraints.

● Utilization of resources like trucks and manpower can be made more optimal with the help of digitization.

● The integration of suppliers', service providers', etc. data in the supply chain cloud ensures that all stakeholders decide on the same facts.

Challenges in digitization before the manufacturing industry

Digital waste prevents the manufacturing industry from leveraging the full potential of the supply chain. In order to know exactly how AI is used in the manufacturing industry, it is important to understand the sources of waste and develop solutions to reduce or avoid it in the future.

● Data capturing and management – Data is often handled manually. Master data that is entered once and then remains unchanged for years causes it to become outdated.

● Integrated process optimization – Integration is a process that is done in silos, and not all information is leveraged to achieve the best planning result possible. Improvement potential created by increased transparency is not realized.

Conclusion

Digitized supply chains, facilitated by IoT, face recognition, and other tools, revolutionize manufacturing. Enhanced efficiency, collaboration, and resource utilization lead to dynamic planning and optimized processes. Challenges like digital waste must be addressed for industries to fully leverage the potential of digitization.

Comments

Post a Comment